NEW: RK Monitor mounting with ball joint

Monitor mounting with ball joint - 60° free swivelling

VESA or universal mount for connecting monitors, displays or control panels

Monitors, touch screens, displays and control panels

are used every day, and not just in the office. Industrial machines and

systems are programmed or performance data displayed on modern touch

screens or control panels. In utility vehicles, camera monitoring

systems facilitate resetting and navigation devices make positioning

possible. On conveyors, monitors make it possible to monitor and

visualise all sorts of processes. Today, control panels or flat screens

are often an essential component of modern assembly workstations, too.

Standard monitor holders and their disadvantages Standard systems are generally designed for office applications. Industrial environments push these monitor mountings to their limits. For example, they normally can carry loads of only six to twelve kilograms and are not robust enough for use on machines, systems or assembly workstations. If exposed to vibration, shocks or frequent adjustment, the ball joints often used do not provide sufficient hold or have a limited lifetime. Another common problem is undesired adjustment.

Standard monitor holders and their disadvantages Standard systems are generally designed for office applications. Industrial environments push these monitor mountings to their limits. For example, they normally can carry loads of only six to twelve kilograms and are not robust enough for use on machines, systems or assembly workstations. If exposed to vibration, shocks or frequent adjustment, the ball joints often used do not provide sufficient hold or have a limited lifetime. Another common problem is undesired adjustment.

Requirements for monitor mountings for industrial applications

RK monitor mountings stand up to the tough demands of day-to-day industrial use

The demands on a monitor mounting in industrial use are high:

They should have a higher load-bearing capacity and be vibration-proof.

In addition, they should meet the requirements for an ergonomic workstation.

This means that it should be possible to adjust all degrees of freedom

independently and separately, and without tools. Then it must reliably

hold the device in the set position even if exposed to shocks. Another

important requirement for a versatile monitor mounting is that it is

flexible in how it fixes to a machine/system and the fitting dimensions

of the devices. Often users make do with complicated self-made or office

solutions, or oversized support arm systems. These solutions prove inadequate in the industrial environment in the long term or may be much too expensive.

Monitor mountings should offer flexible adjustment

Monitor attachment via VESA or universal mount

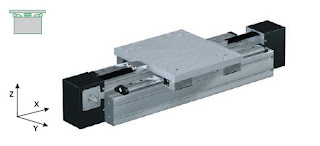

The RK monitor mounting is flexible: Choice of tube-mounting or wall-mounting, VESA or universal mount

One great advantage of the brackets is the flexibility they offer

for device fitting dimensions and for installation options. The user can

mount the screens/control panels via a VESA Standard 75/100

connecting plate – in other words, with a 75 x 75 mm or 100 x 100 mm

mounting hole pattern – or a round aluminium universal mounting surface.

Thus, in principle, just about any panel can easily be connected up

without special components.

The monitor mounting can be mounted in the slot of any aluminium profile system using slot stones, or on any other tube, profile or any wall. The screws and slots stones required for installation on an RK profile system are

included in the scope of delivery.

The RK monitor mounting is made of an optimised mix of materials: The

wall mount and connecting plates are made of aluminium, the tube connectors

of high-strength plastic. Since the construction consists of optimised

RK standard products, the monitor mounting, including all installation

options, is economical and available in no time.